- Home

- Product

>

-

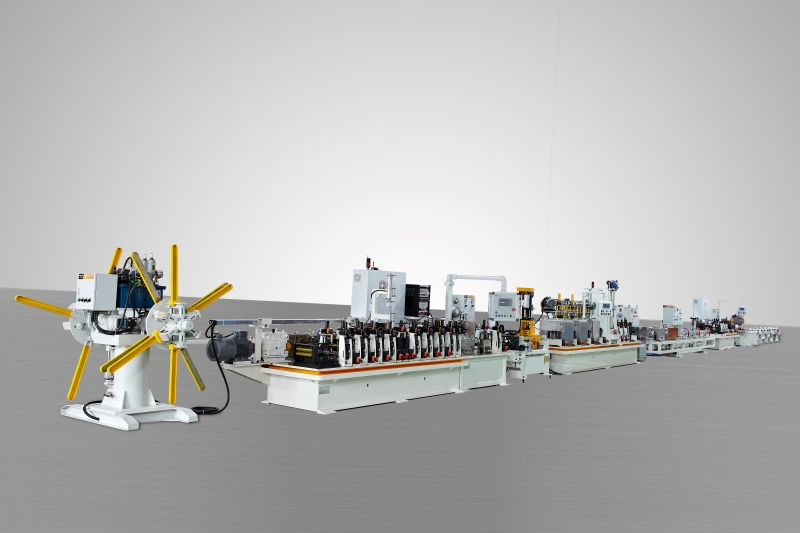

Stainless steel air conditioning pipe production line

-

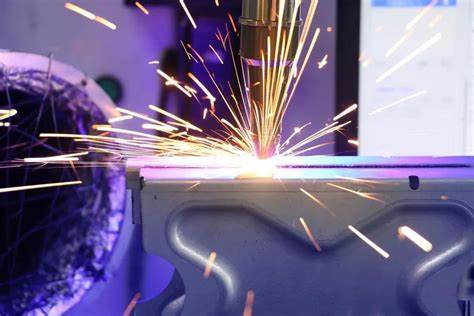

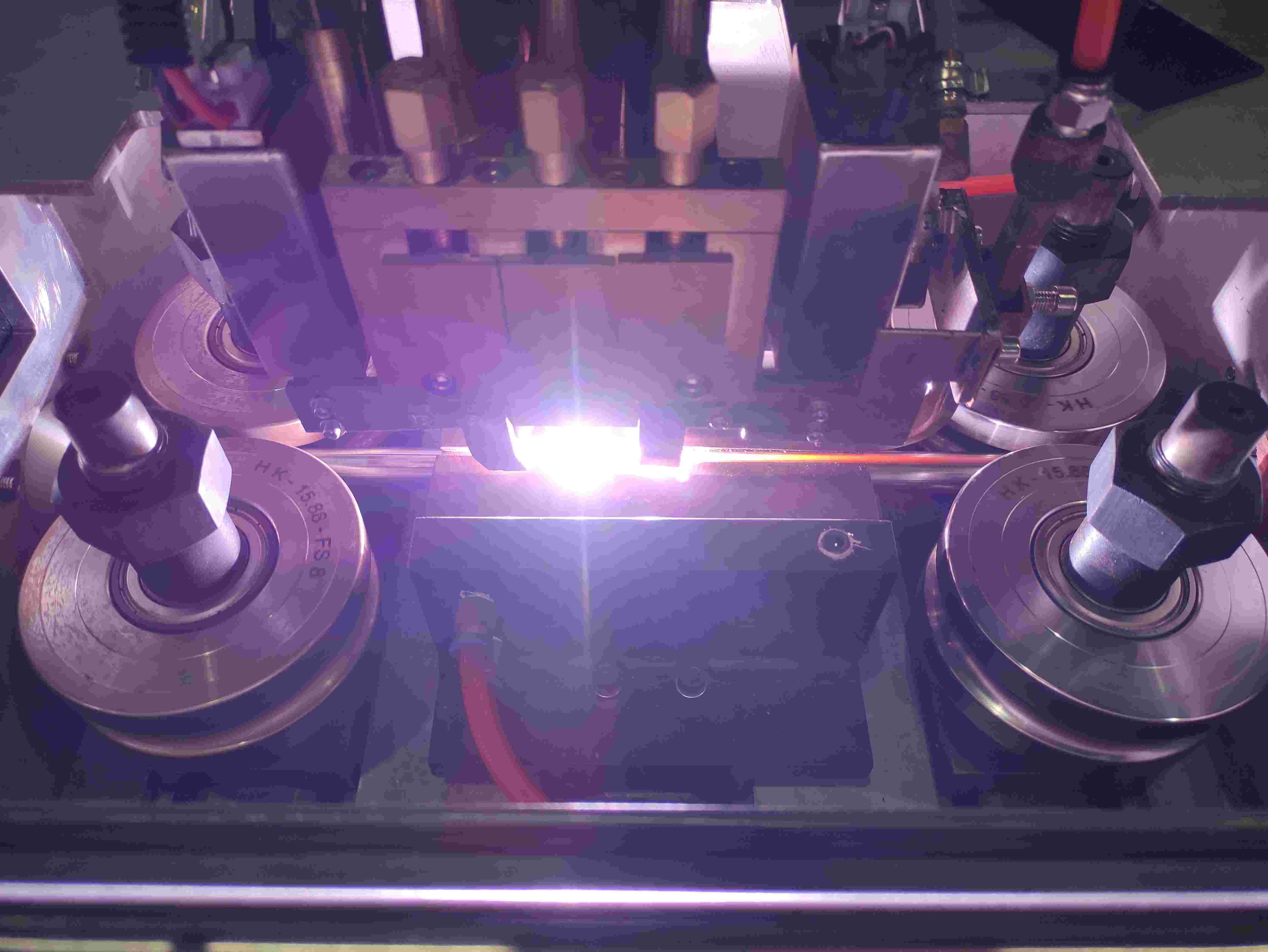

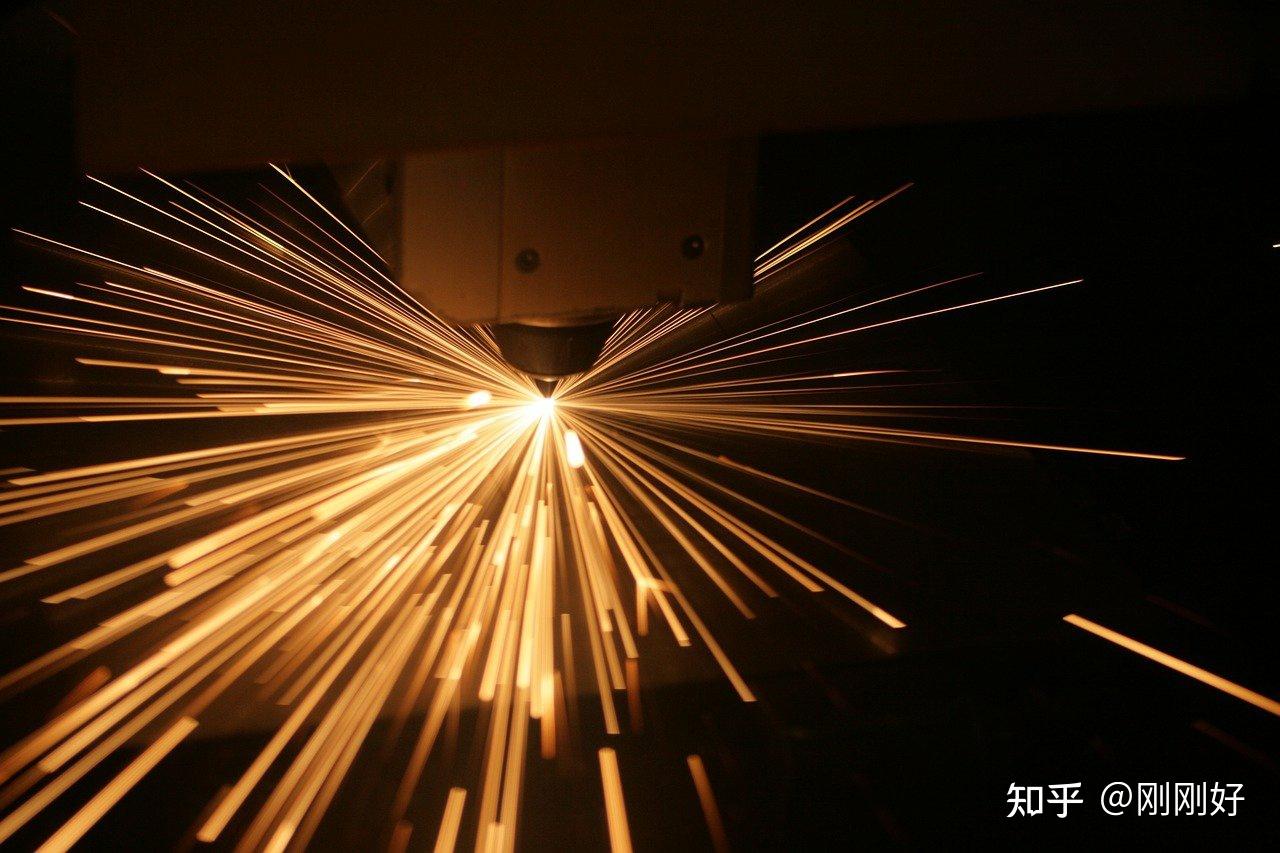

Precision Welded Pipe Production Line

-

Rotary Black Annealing Production Line

-

Induction Finished Tube Bright Annealing Production Line

-

Weld Bead Roller Machine

-

Annealing Machine

-

Auxiliary Equipment

-

- About Hangao

- News

- Video

- Contact

- CN

menu